A customer orders at 10 PM. By 11 AM the next day, they expect it to be shipped. Miss that window twice, and they’re gone to a competitor who won’t miss.

That’s the reality of running an ecommerce business today. Your ecommerce warehouse isn’t a storage room anymore, but has become the engine behind every promise you make on your product page, like “ships in 24 hours,” “same day delivery to prime customers”, “easy returns,” “always in stock.”

Here’s what most sellers learn the hard way: the gap between a ₹50 lakh business and a ₹5 crore business isn’t marketing. Its operations. Specifically, how well your warehouse handles volume without bleeding money or dropping orders.

This guide covers the operational architecture behind profitable ecommerce warehousing, including how to choose the right warehouse facility type and location, implement systems that actually scale, and fix the inventory and fulfillment mistakes that quietly kill margins. Whether you’re shipping from a spare room or managing multiple fulfillment centers, this is the strategic foundation.

What is an eCommerce Warehouse?

An ecommerce warehouse is a specialized, well-equipped area used to store, manage, and ship products sold online.

Some are managed by the person who rented them out as their personal fulfillment center or storage, while others are managed by third-party fulfillment providers.

Change is constant—warehouses must evolve too. Regularly seek opportunities to improve efficiency and functionality.

Warehouses act as the operational link between inventory intake and last-mile delivery.

For ecommerce businesses, a warehouse is essential. When done with a proper ecommerce warehouse management system (EWMS), it not only improves your business’s functionality but also reduces errors, helping your brand stand out from the others.

With this understanding of warehouses, it is important to explore their various types.

Also Read: Types Of Warehouses For ECommerce

Types of Warehouses for eCommerce

The optimal warehouse type for your ecommerce business depends on storage volume and product type.

Here are some of the most common types of warehouses for eCommerce that you can choose from:

| Warehouse Type | Best For: | Monthly Cost Range (per square foot) | Setup Time Required | Key Benefits |

| Public Warehouses | Startups and Small-to-Medium Sized Businesses | ₹12 to ₹25 per sq. foot | 1-2 days to 3-4 weeks | Saving costs, Flexible, Scalable, and Strategic Location Choice |

| Private Warehouses | Larger corporations, Manufacturers, Wholesaler | ₹15 to ₹40 per sq. foot | Few weeks to few months | Better Security, Operational Control, Supply Chain Integration |

| Fulfillment Centers | Retailers, Fast-growing brands, and high-volume B2C businesses | ₹45 to ₹85 per sq. foot | Few weeks to few months | Faster and Cost-Effective Shipping, Better Inventory Management |

| Smart Warehouses | High-Volume Retailers, Business for perishable goods | ₹20 to ₹50 per sq. foot | Few months to 3 years | Increased efficiency and productivity, Lower Labour Costs |

| Bonded Warehouses | Importers, Exporter and Manufacturers in International Trade | ₹25 to ₹60 per sq. foot | Few weeks to few months | Deferred Duties and Taxes, Extended Storage Time |

| Consolidated Warehouses | Retailers with Multiple Suppliers and Consumers. | ₹18 to ₹40 per sq. foot | 1 to 6 months | Lower Transport Costs, enhanced inventory management |

| Co-operative Warehouses | Agricultural Businesses, SMEs, and Local producers | ₹10 to ₹30 per sq. foot | 1 year to 2 years | Shared resources and space, Cost-efficient |

| Government Warehouses | Cargo-based businesses, with longer storage | ₹10 to ₹25 per sq. foot | 3 months to 2 years | Very high security, Cost-effective, Compliance Advantages |

| Distribution Centers | Ecommerce retailers, wholesalers, and manufacturers | ₹18 to ₹30 per sq. foot | 2 months to 4 months | Faster Order Fulfillment, Less Transport Costs, Better Customer Experience |

Source: WadiGroup, Kishore Infratech, Safe Storage, Bhandaran Nigam, Vestian, ET, MFPI,

Public Warehouses

Public Warehouses are facilities that businesses can rent as needed, providing a cost-effective solution for startups, businesses with fluctuating inventory needs, or during peak season, as they allow businesses to scale without long-term commitment.

Private Warehouses

Generally owned by larger corporations, Private warehouses not only provide storage and management but also allow the entire business to be operated on-site.

Private warehouses are owned by a specific organization. When a company opts for this, it means they have full control over operations, technology, security, and more.

Fulfillment Centers

Fulfillment Centers are among the most common types of warehouses, playing a critical role in the e-commerce industry, which requires quick order fulfillment.

These centers are third-party logistics (3PL) facilities specialized in managing inventory, processing orders, packing, shipping, and, in some cases, delivery. It helps with rapid delivery to end users, and well-known brands like Amazon use these centers for their 1-day delivery (Prime customers).

Quick order fulfillment is a strong growth strategy, and fulfillment centers support this need.

Smart Warehouses

Adopting technologies such as AI, robotics, and IoT can transform your ecommerce warehouse. These advancements enable real-time inventory tracking, automate repetitive tasks such as sorting and picking, improve accuracy, and provide actionable analytics, leading to faster, more efficient order processing.

If you need these features, a smart ecommerce warehouse management system is essential. Though setup costs are high, long-term labor savings balance this investment.

Most tech-based businesses prefer a smart ecommerce warehouse management system because it automates their operations and, in most cases, delivers real-time data.

Bonded Warehouses

Bonded warehouses are facilities in ports where importers store goods without paying customs duties until a buyer is found. These facilities are secure, custom-supervised, and have recently been used on a large scale to navigate the volatility caused by U.S. tariffs.

According to a Reuters report, when U.S. tariff threats sent copper prices in America soaring, traders began draining Chinese bonded warehouses. Instead of waiting for tariffs to reduce, exporters rushed to ship the metal stored in these warehouses directly to the U.S. and Europe to profit from the massive price premiums.

This flexibility makes bonded warehouses highly appealing in cross-border trade and the import/export business.

Consolidated Warehouses

Relatively inexpensive, this approach is preferred by ecommerce SMBs starting out. Receiving small shipments from various suppliers and grouping them before distribution reduces capital investment and inventory volume.

Low costs and no restrictions make this ideal for businesses serving the same area.

Cooperative Warehouses

Larger businesses and manufacturers opt for private warehouses to gain more space and operational control.

Co-operative warehouses are shared facilities for businesses. Sharing a large space can limit total control, but it also minimizes costs for each company.

Small and medium businesses choose co-operative warehouses mainly for cost savings.

Government Warehouses

Supply chains that are directly or indirectly controlled by the government, such as seaport storage facilities, have government warehouses, where corporations or local authorities store goods, particularly agricultural goods.

Governments charge reasonable rates, but unpaid rent can result in the disposal of goods.

Distribution Centers

Distribution Centers generally have a clear purpose of efficiently receiving, storing, managing, and redistributing goods. The storage time is very limited, as bulk inventory is rolled out over a very short period.

Perishable items, such as food, are distributed from a distribution center.

Selecting the Right Warehouse: Strategic Decision-Making

India’s eCommerce warehousing market reached $10 billion in 2025 and is expected to grow to $39.1 billion by 2034, with a compound annual growth rate (CAGR) of 16.42%. This rapid growth reflects how online businesses are prioritizing warehouse efficiency, scalability, and operational control to meet rising delivery expectations.

Choosing the right warehouse goes far beyond rental cost. Location, space planning, technology readiness, and integration with fulfillment operations all directly impact delivery speed, operating costs, and customer experience.

A well-chosen warehouse doesn’t just reduce expenses — it becomes a long-term growth enabler.

Here’s how to evaluate a warehouse strategically:

- Warehouse Location

Choosing the right location for an ecommerce warehouse significantly affects total cost. If your warehouse is poorly located, deliveries slow down, and operational costs rise.

Creating distinct distribution zones around the warehouse, checking roads, and assessing connectivity factors are key, as they affect delivery speed.

Efficient inbound and outbound logistics require accessible warehouse locations, ideally connected to major highways and uncongested roads. Evaluate these factors carefully when selecting a site.

- Technological Advancements

Advanced warehouse technology helps automate processes such as receiving, picking, and packing. Real-time inventory tracking across sites prevents stockouts and overstocking, improves accuracy, and enables more efficient decision-making based on up-to-date data.

- Safety and Compliance

Verify full legal compliance and robust security before selecting a warehouse. Essential features include secure access, surveillance, and guards. In India, choose GST-compliant warehouses to streamline paperwork and avoid tax penalties.

- Consider Warehouse Logistics

While strategizing to choose your warehouse, the primary decision a business has to make is whether to rent a whole warehouse to itself, retaining full control, or to contract with a third-party warehouse logistics provider (3WLP).

The decision depends on factors such as the scale and requirements of the business.

For most growing brands or startups, it is generally preferred to pay only for the space you use. This saves a lot of cost while avoiding the need to build a warehousing network yourself.

Also Read: Factors To Consider While Selecting A Warehouse

Warehouse Systems and Technology for Operational Efficiency

Tech systems can make operating in and out of your warehouses more efficient. It increases speed and accuracy and, in general, reduces costs.

Automate and track warehouse operations with the right technology for easier management.

Warehouse Management System & How It Works

Warehouse Management System (WMS) is software that lets you manage and control ecommerce warehouse operations and track inventory in real time.

A WMS provides tools for picking, packing, resource utilization, dispatching, and analytics.

Most useful once order volume increases, a good WMS provides a single dashboard for all facets of inventory tracking and replenishment.

This includes all the core functions of a WMS: inventory tracking, bin mapping, picking, packing, and dispatch.

Integrations are another important aspect, and Warehouse Management Systems generally integrate with other tools, ranging from basic to advanced.

Here are some of the common integration tools used with a WMS:

- E-commerce Platforms such as Shopify and more

- Enterprise Resource Planning (ERP)

- Order Management Systems (OMS)

- Customer Relationship Management (CRM)

- Transportation Management Systems (TMS)

- Courier Systems such as UPS and FedEx

Warehouse Automation

As order volumes grow and operations become more complex, relying on manual warehouse processes quickly becomes unsustainable.

Options for ecommerce warehouses range from automatically scanning parcels to sorting them in the correct order.

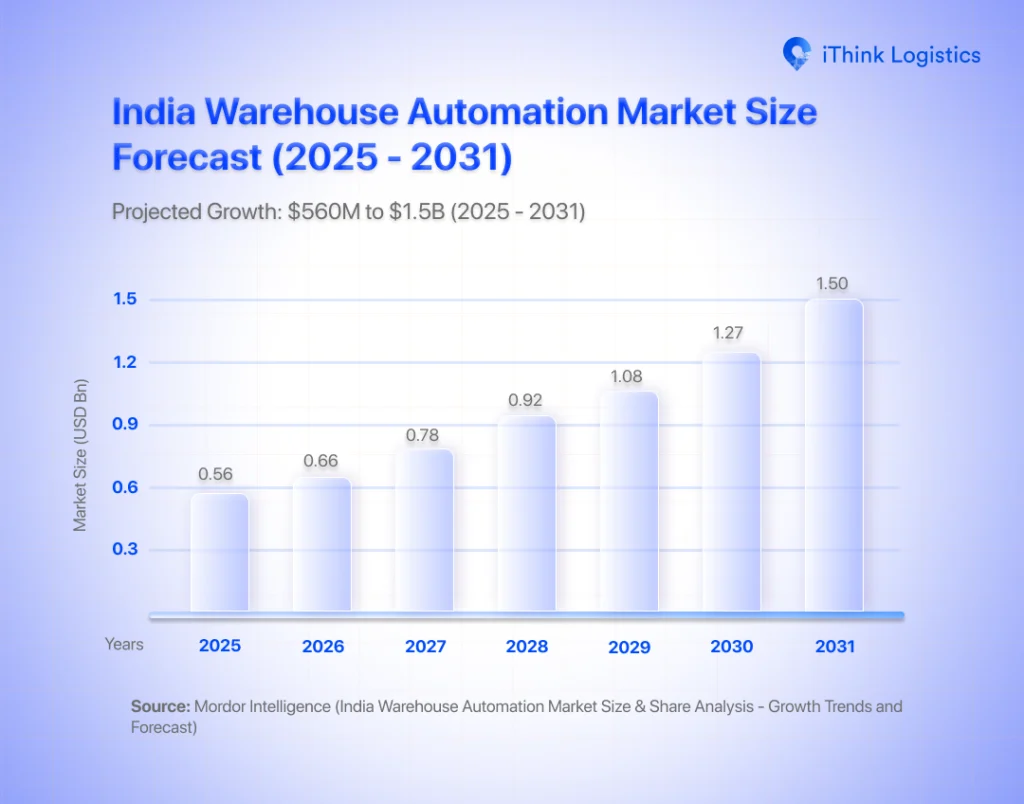

Some estimates suggest that India’s warehousing automation market is expected to grow from USD 560 million in 2025 to USD 659.96 million in 2026 and USD 1.5 billion by 2031 at 17.84% CAGR over 2026-2031

Here are some of the tasks that can be automated in a warehouse:

- Using WMS software will automatically print shipping labels for all orders, eliminating manual printing.

- Tracking every single moving piece in your warehouse is also possible through automation. Sensors, technology, and automated storage are a few ways to make it possible.

- Future inventory needs can be forecasted, and automatic reordering can help save time.

- Using Storage and Retrieval Systems along with goods-to-person systems, the right products are picked and packed every time, without the risk of human error.

Now that you are aware of most of the details about warehouse automation, you must also know which tasks can benefit the most from automation. The simple answer to this question is the picking, packing, and shipping process.

Also Read: Warehouse Management System: How It Works?

Warehouse Hygiene, Safety, and Risk Management

Properly organizing goods, maintaining a sanitized storage area, and proactively eliminating hazards are fundamental to warehouse hygiene and risk management.

This includes defined cleaning schedules, designated waste-disposal zones, and hygiene SOPs across storage, packing, and dispatch areas.

How to keep your warehouse clean and safe?

Training your staff to clean the floors and equipment that are used almost on a daily basis, such as the equipment in the packing area or even switches. The staff should also be ready at any time for emergencies.

Whenever a product is damaged, the sooner it is thrown away, the better it is for the rest of the non-contaminated goods.

Doing safety routine checks as frequently as possible is always a good idea to ensure a certain level of hygiene is maintained in the warehouse.

Importance of risk management in warehouses

At any given time, keeping track of all potentially hazardous things is fundamental. Here are some of the common risks to keep an eye on:

- Risk of Fire

- Risk of Flood

- Risk of Power Outage/ Short Circuit

- Crashes/Collisions

- Cuts

- Falling Objects

- Mishandling of Machinery

- Over capacity attempt (Overexertion)

- Damage to Inventory

Applying for insurance can reduce the loss of business incurred from a warehouse accident.

Picking Systems: Speeding Up Fulfillment Without Errors

Picking systems in modern warehouses rely on WMS, automation, barcodes, and AI-driven processes to reduce errors while increasing fulfillment speed.

Picking is the process of gathering all the products needed to fulfill a particular customer’s order.

The best picking systems make you save your time while fulfilling orders and minimizing errors.

- Single Order Picking

Grouping orders by features and dimensions is what you might call “Single Order Picking”. In this picking system strategy, items that fit into a group rather than others are hand-picked by a person, packed, and labelled before delivery.

- Zone Picking

Zone Picking is a warehouse logistics fulfillment strategy where the facility is divided into multiple zones, with operators assigned to pick items for their zone for delivery. The criteria for dividing things into two or more different zones depend on demand levels, storage conditions, and the number of SKUs.

- Batch Picking

When operators properly locate the Stock Keeping Unit (SKUs) and sort them before sending them to the consolidation area, it is batch picking. Then, they are sent out for orders without much issue since the SKUs of all those products are pretty much the same.

- Wave Picking

Completing multiple orders at once gets easier with wave picking, which groups products in a cart. This sorting process depends on all the basic criteria already mentioned in the blog.

Inventory Management and Stock Accuracy

Managing inventory at any given point in time in an ecommerce warehouse and being fully aware of when to reorder a particular product will help you maintain a certain level of stock accuracy.

Here are detailed lists to give you an overview of everything you need to know or keep in mind regarding inventory management and stock accuracy:

8 Tips To Optimize Inventory Management

Here are some brief tips to make the best out of your inventory management

- Converting data to business intelligence. In an increasingly saturated market, having all the data on your inventory, sales, and the business as a whole helps you grow and stay in it.

- Classify your inventory properly. This will help you group your inventory and give you precise control over every inventory category.

- Having an ecommerce warehouse management system (WMS) is also very beneficial. Try to avoid Spreadsheets, as they’re extremely error-prone and cost your business more than they help.

- Having safety stock levels will definitely serve as a warning when stock levels fall low. A better floor plan ensures better order fulfillment during changing seasons.

- Routine audits are important because, even though the counting process can be easily automated, having a human count the stock manually every once in a while can help you take mediocre inventory management to an expert level.

- Prioritize your business’s needs rather than including every feature. If your business does not need to support barcoding, for example, or chat support for mobile sales, these are the features you can opt out of.

- Maintain optimal inventory levels by balancing inflow and outflow rates and tracking product movement. Faster-moving inventory reduces damage and obsolescence risk, prevents capital from being tied up in slow-selling SKUs, and helps businesses stay competitive without stockouts.

- Customers with large or frequent orders should be given priority. Many businesses use the good old method of colour coding to differentiate between serious customers and others.

Cycle Counting vs Annual Inventory Counts

To determine if cycle counting or annual inventory counting is better for your business, you must consider a few factors.

Does your business need to improve its inventory tracking, or would a full inventory audit be more effective?

These are the questions you must ask before deciding how to structure your business’s inventory cycle.

Here are some of the benefits of each, so that your decision-making process becomes easier:

6 Benefits of cycle counting vs Annual counts

- Cycle counting will help you maintain accurate inventory throughout the year.

- Retail, manufacturing, and distribution businesses.

- Disruption in warehouse operations on a larger scale is avoidable when counting is done in sufficient cycles.

- Reducing stockouts is another benefit of cycle counting, as it helps you know the number of stock available at any given time.

- The number of errors is drastically reduced, and almost no calculations are needed based on estimates.

- Better sales and customer service overall.

Benefits of Annual Counting over Cycle Counting:

- For small warehouses with limited inventory inflows and outflows, Annual Counting may be preferable.

- Maintaining financial records and ensuring tax valuation at the end of each year is purposeful.

Improving Customer Experience Through Warehousing

Ecommerce warehouse management system improves customer experience for both product-based businesses and service-based businesses.

In product-based businesses, reducing wrong shipments, accelerating order fulfillment, and providing transparent, real-time details to customers are beneficial.

Improving Customer Service Through Warehouse Management

A well-operating warehouse helps businesses meet customers’ needs on time, thereby increasing customer satisfaction.

One of the most important times to focus on customer satisfaction is during peak periods. Managing inventory and fulfillment of orders properly during peak seasons, when a lot of customers need bulk products at the same time due to festivals or any other reason.

Missing items, late deliveries, and incorrect shipments should be minimized to the lowest possible levels to improve the customer service your business provides.

Shipping and Fulfillment From Home to Large-Scale Warehousing

Shipping and fulfillment do not always require a large warehouse. Apart from the requirement factor, however, you will have to realise that many small businesses cannot afford warehousing.

Does that mean you will not be able to fulfill your orders or provide customer satisfaction? Absolutely not.

Here is how you can make the best out of shipping from home.

Scaling Up From Home Shipping to a Warehouse

There comes a time when you will realise, on your own, that home shipping will not be sufficient for the scale of your business once it has grown to a certain point.

Here are the signs that you need to look out for when making the transition from home shipping to warehouses or fulfillment centers:

- Manual tracking is getting near impossible.

- Storage space is insufficient for efficient operations.

- Shipping costs are getting high, and it takes almost the whole day to pack.

Once you notice these signs, you know it is time to make the transition, but it does not happen overnight. At that time, it is very important that your delivery process is not hampered.

Here’s how you can ensure that:

- To avoid interrupting sales, try a hybrid approach: keep half of your inventory at the existing warehouse (or your home) to keep operations going. At the same time, some of the inventory can be sent out to the warehouse locations.

- Proactive communication with the warehouse you are renting next is very important so you do not experience inventory shortages at any given time, and keep sales going.

- Off-Peak Time is the best time to move, since during peak seasons, demand is very high, and meeting those demands while moving your inventory to a new place can be quite hectic.

Warehousing and Fulfillment Blueprint for Ecommerce Growth

When your goal is to make the most of your warehouses or fulfillment centers to drive the most ecommerce growth, here is a brief recap of everything mentioned in the blog.

If there were a Warehousing and Fulfillment Blueprint for business growth, it would suggest choosing the right warehouse locations based on your products and service areas.

Another really important thing is to use automation to reduce human labour while increasing the speed of operations and the accuracy of the data available to a business.

Choosing the right picking systems increases operational efficiency in and out of the warehouse or fulfillment centers, while managing stock and equipment will definitely reduce losses not just for the warehouse but also for the ecommerce business as a whole.

Conclusion

Your warehouse strategy matters more than you think. Your warehouse strategies definitely add to the ultimate fate of your business- scalable or struggling. This blog was a definitive guide on how to make your warehouse add to the credibility of your ecommerce business.

These days, a warehouse is more than a storage facility; it’s a growth engine for any ecommerce business, especially with the inclusion of fulfillment centers and a variety of rental options.

Across warehouse types, technologies, and fulfillment models, one pattern remains consistent: businesses that treat warehousing as a system, not a space, scale faster with fewer operational failures. Location decisions, inventory discipline, picking logic, and automation only work when they are designed together, not in isolation.

Choosing and properly managing the right warehouse or warehouses will reduce delivery time, increase customer trust, and lower operational costs, thereby growing your business.

FAQs

Q.1: What’s the difference between a fulfillment center and a regular warehouse?

A: A regular warehouse mainly stores inventory, while a fulfillment center is built for fast order processing. Fulfillment centers (3PLs) handle picking, packing, shipping, tech integrations, and courier coordination, often enabling same-day or next-day delivery. Traditional warehouses focus on storage with limited value-added services. For businesses processing 50+ orders a day, fulfillment centers justify their higher cost through speed, accuracy, and automation.

Q.2: When should I move from home shipping to a professional warehouse?

A: You should consider moving when you consistently process 300–500 orders per month, spend several hours daily packing, or face frequent inventory and shipping errors. Other signs include running out of storage space or shipping costs eating into margins. A safe approach is a hybrid move—keep part of your inventory at home while testing warehouse operations during a non-peak period.

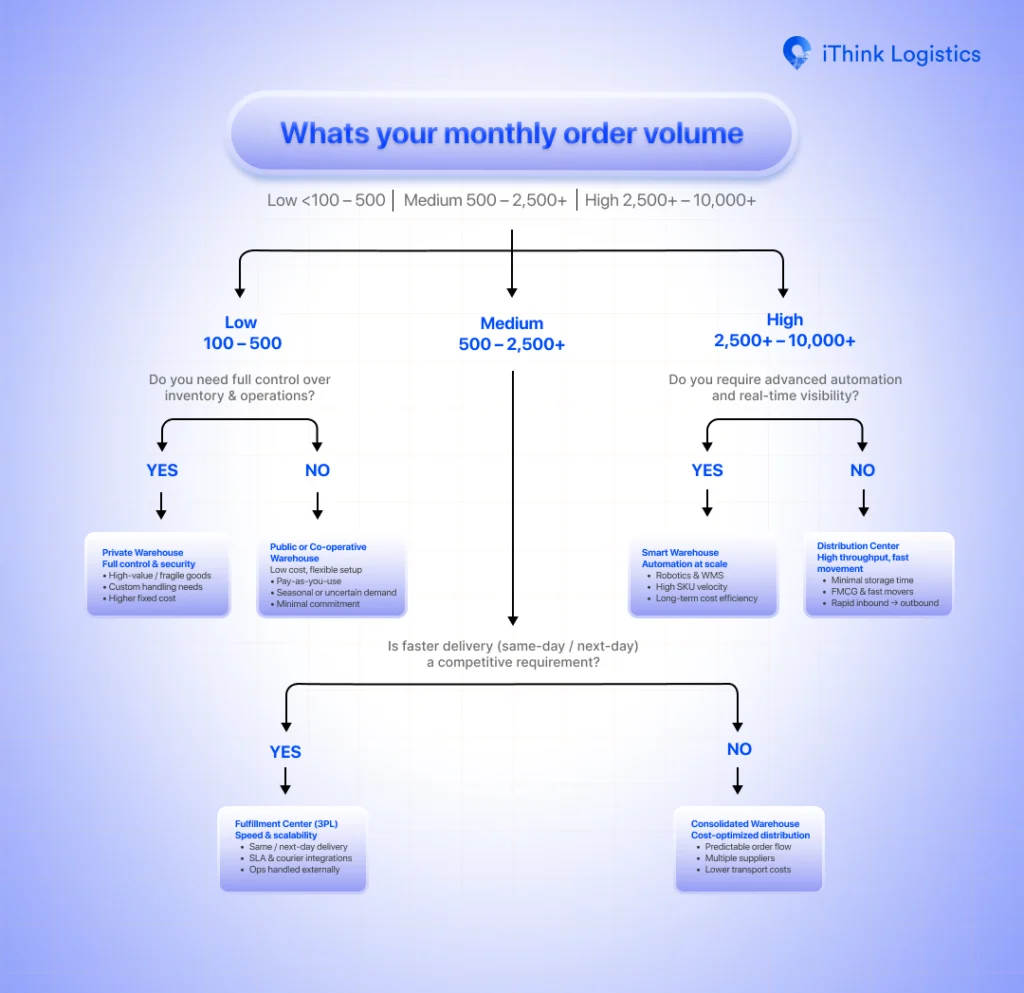

Q.3: How do I choose the right type of warehouse based on my order volume?

A: Low volume (<500 orders/month): Public or Co-operative warehouses (₹12-₹30/sq ft) for flexibility and low costs.

Medium volume (500-2,500/month): Fulfillment centers (₹45-₹85/sq ft) when fast delivery matters.

High volume (2,500+/month): Smart warehouses with automation or distribution centers for rapid turnover.

Private warehouses only make sense for high-value goods needing custom handling or when exceeding 5,000+ orders/month for long-term cost efficiency.

Q.4: Do I really need a Warehouse Management System (WMS), or can I use spreadsheets?

A: Spreadsheets become risky beyond 20–30 orders per day. Manual updates cause overselling, stock mismatches, and fulfillment errors. A WMS is essential once you manage multiple sales channels, handle 30+ SKUs, or need real-time inventory visibility. Even basic cloud WMS tools significantly reduce errors and improve picking speed.

Q.5: Which picking system should I use: Single Order, Zone, Batch, or Wave?

A: Single order picking suits small setups with fewer than 50 orders a day. Zone picking works well for growing warehouses by reducing walking time. Batch picking is ideal when many orders contain the same SKUs. Wave picking fits high-volume operations with peak-hour planning and requires a mature WMS. Most businesses progress through these methods as volume grows.

Q.6: What’s the difference between cycle counting and annual inventory counts?

A: Annual counts require stopping operations once a year and often miss ongoing issues. Cycle counting checks inventory in small, regular intervals throughout the year, keeping accuracy above 98% without disrupting sales. For ecommerce businesses with daily order movement, cycle counting is more reliable and operationally safer.

Q.7: How does warehouse location impact delivery costs and speed?

A: Warehouse location directly affects transit time and shipping rates. Being closer to your main customer clusters reduces delivery time by 1–2 days and lowers per-order shipping costs. Good highway access and proximity to courier hubs further improve pickup speed and reliability. Poorly located warehouses increase costs and delay deliveries.

Q.8: Is warehouse automation worth it for a mid-sized ecommerce brand?

A: Automation is worth it when order volume and SKU velocity are high. Most mid-sized brands see break-even in 3–4 years. Starting with simple automation—barcode scanning and automated label printing—can cut packing errors by up to 90% without heavy upfront investment. Full automation makes sense as daily orders cross 200+.

Q.9: What is a bonded warehouse, and when does an ecommerce business need one?

A: A bonded warehouse allows importers to store goods without paying customs duty until the items are sold or moved out. This improves cash flow and supports cross-border trade, especially near ports. You only need a bonded warehouse if you regularly import goods; domestic-only sellers don’t require one.

Q.10: What’s the difference between 3PL and 4PL, and which one do I need?

A: A 3PL manages warehousing, picking, packing, and shipping for your orders. A 4PL oversees the entire supply chain, coordinating multiple 3PLs and optimizing logistics strategy. Most ecommerce brands only need a 3PL. 4PLs are suited for enterprise-scale businesses operating across regions or countries.

Leave a Reply